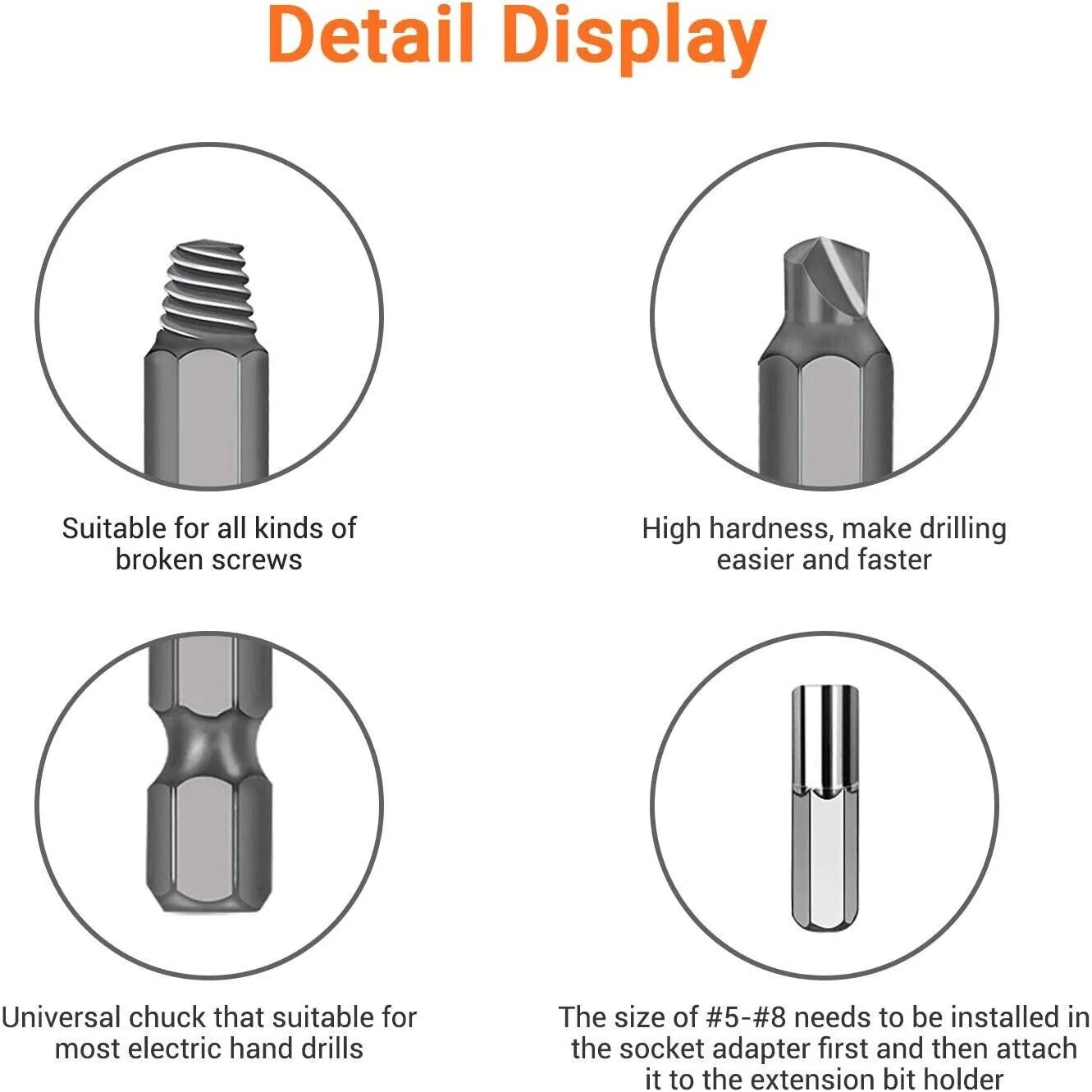

▲ [Smart Design] – Working together with an extension bit holder and a socket adapter, burnishing bits and extracting bits designed separately enables casual changes of the bits without flipping, timeless and effortless for work

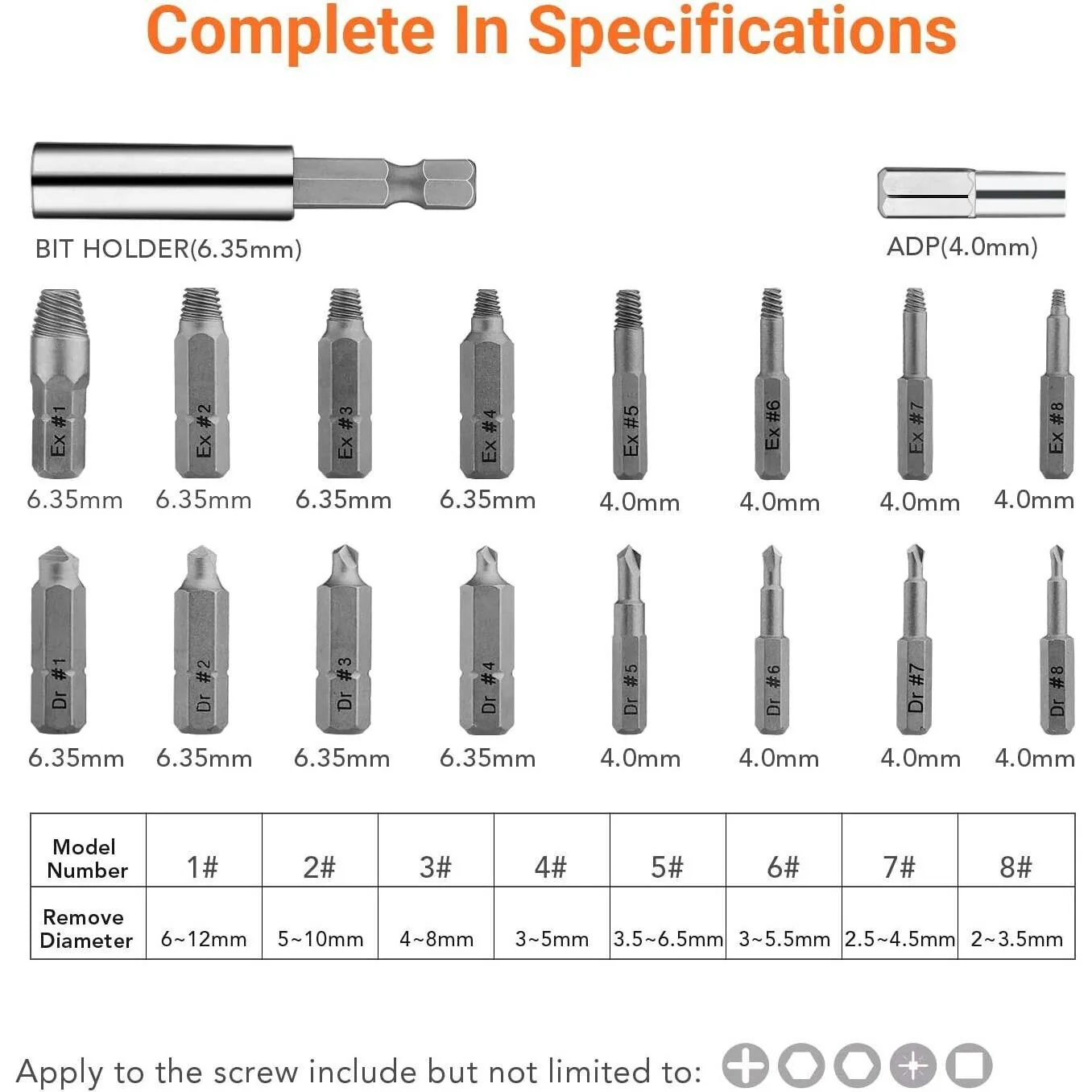

▲[ Industrial Grade] – Tack life 18pcs damaged screw extractor set covers higher possibility of extraction for more broken screws or bolts of different sizes(2-12mm) and the self-centering drill tips can work on jagged, uneven rough breaks

▲ [Adequate Quality ]- S2 material (hot work die steel) with maximize rust and corrosion protection, hardness can reach to 62HRC for strength, flexibility and durability; Serrations on extractor(collect) result in greater torque for hard to remove bolts

▲ [Powerful Fittings Supply] – Extension bit holder(6.35mm,1/4”) and socket adapter (4mm, 5/32” ) of the screw remover set suits all the brand household electric drills; Magnetism inside the holder and adapter keeps the bits from dropping, so do small bolts or screws

▲ [Easy for Use] – Separate drill bits and stripper bits simplified the entire process. You do not have to turn over the extractor or re-tension the drill chuck for extraction

Easy to Use

➤Separated burnishing (drilling) bits and extractor bits simplify the whole process, you don’t need to flip the extractor and rotate the drill chuck again for extracting then

➤All the bits can be applied to any electric drills with or without the extension bit holder or Adaptor, depending on where the bolt is

➤Effortless switches of extension bit holder and socket adapter makes the little details of daily work enjoyable. No grinding or centre punching required.

➤A clip on the back of the tool case helps carry the small package everywhere you go and close at hand

Instructions of Usage

Change the speed of the electric drill under 400RPM, and press rotational switch reverse

For bolts on flat surface, install with or without the extension bit holder into the drill and fully twist the drill chuck on; For bolts in a cramped space, the extension bit holder will be obviously needed

Select a suitable drilling bit according to the specifications attached beside the bits with #1-8, then drilling a hole in the middle of the screw until the hole deep enough to be damaged

Install the correspondent size of the extractor(collet) and then remove the damaged screw counterclockwise until it is released